What Causes Lamination In Steel

Solid composite has a bright sound while a delaminated part sounds dull.

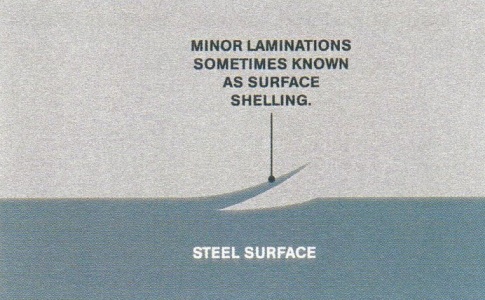

What causes lamination in steel. An imperfection in a coil of steel resulting from blisters seams foreign material and or scratches on an ingot or billet of steel that are not repaired during the rolling process. A variety of materials including laminate composites and concrete can fail by delamination. Reactor was removed and replaced with a new reactor because of the laminations that occurred at depths of 11 5 12 mm and 6 7 mm in the wall thickness of 18 mm. The deflection causes the steel piece to be thinner on the edges and thicker in the middle.

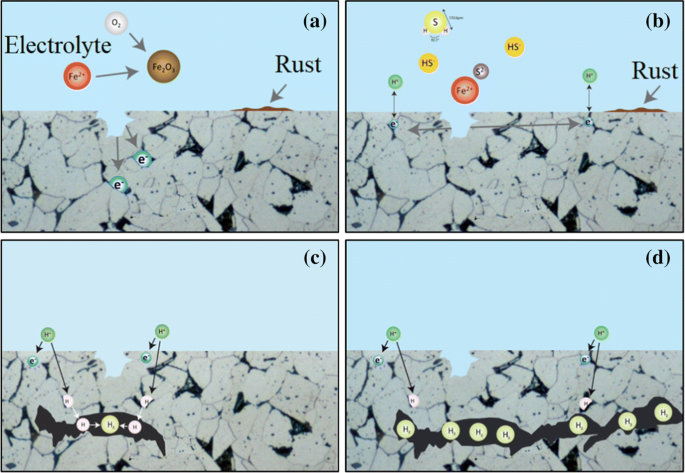

Plain carbon steel steam pipe. The cause of delamination is weak bonding. Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation. Because inclusions and laminations are not always found throughout an entire bar plate or other form we should attempt to work through the issue.

It was an extruded material. The carbon steel blister in photograph would be an exception to that comment. Small laminations may also be welded over and blended polished back into the base metal. The laminations are excellent places for the h to collect and can actually cause bubbles to form in the material.

Laminations are large porosity pipe and non. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure. Delamination is a mode of failure where a material fractures into layers. If you weren t careful.

These laminations were found after 7 years of operation. At the end of the day nobody really wants laminations in their materials but you will only actively look for them when they will be a problem. Both of the vessels were manufactured together from the same steel stock and were working with similar chemicals. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels.

Delamination failure may be detected in the material by its sound. This can be overcome by using a crowned rolls parabolic crown however the crowned rolls only compensate for one set of conditions specifically the material temperature and amount of deformation.